Locust bean gum or Carob bean gum (ELGUM) is a galactomannan extracted from the seeds of carob tree which are present inside the long fruit pods of the tree. Carob powder is obtained from the fruit pod after removing the seeds of Locust Gum, whereas the gum is extracted out from the seeds.

The carob fruit pods are the edible part of the carob tree & are used as a natural sweetener & thickener in foods. The pods are brown, elongated, compressed & contain hard seeds inside. The pods can be eaten raw or cooked having a sweet & slightly bitter taste.

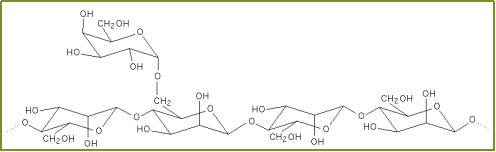

Locust bean gum consists of β-(1,4)-D-mannose units. Approximately every fourth mannose units are substituted with a small side chain consisting of a 1,6 linked α-galactose sugar.

Galactomannan substitution levels are essential to identify various gums. The number of galactose & mannose side chains dictates the type of gum:

| Name of gum | Number of galactose units | Number of mannose units |

|---|---|---|

| Locust Bean Gum | 1 | 4 |

| Tara Gum | 1 | 3 |

| Guar Gum | 1 | 2 |

| Fenugreek gum | 1 | 1 |

| Tagua Nut or Ivory nut mannan | 0 | 1 |

The substitution levels are important as they profoundly impact the properties of the gums because polymannan can couple & is self-cross linkable.

Polymannan is a kind of polysaccharide made of mannose units connected by β-(1,4) glycosidic bonds. The solubility and characteristics of this polymannan depends on how many galactose side chains are attached to it. Polymannan can join with other molecules by forming hydrogen or covalent bonds, and it can also link with itself through intermolecular forces. This self-linking can enhance the mechanical, thermal, and water-resistant properties of materials based on polymannan.

Thus, tagua nut mannan with no galactose units is insoluble & fenugreek gum shows gum properties of a simple random coil structure. LBG shows intermediate properties showing solubility & also shows substantial aggregation in solution.

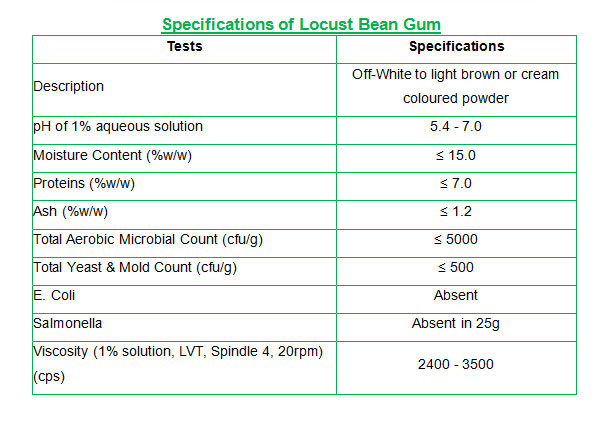

Locust bean gum is a natural branched non-ionic polymer which is off-white to light brownish powder. It is readily dispersed in cold & hot water forming a solution between pH 5.4 to 7.0 & on adding small amount of sodium borate, a gel is formed. It is partially soluble in cold water. Its quality depends on :

LBG is partially soluble in cold water but is completely soluble at about 82°C. It forms a highly viscous solution & forms gels with Xanthan gum upon heating & cooling binding the water molecules. It makes agar & carrageenan more elastic.

Locust Bean Gum

By forming a crystalline region, the mannan sections of the molecule chain become more thermodynamically stable than in the solution state. As a result, the polymer chains tend to aggregate even at ambient temperature when in solution. This is beneficial, as lower water activity and solution temperature can enhance the aggregation and create a 3D network and a gel. This is the same process that occurs in ice cream during freezing. This has two major benefits: first, the ice cream does not have a slimy or slippery mouth feel due to the weak gel structure; and second, the weak gel structure prevents the ice cream from melting quickly when heated.

Carob Fruit Pods

LBG and kappa carrageenan are the main ingredients for making dessert jellies and pet food jellies without gelatin The texture of the gel from LBG and carrageenan can be adjusted to be like gelatin. The gel also melts at a higher temperature, which is useful for areas that are warm or lack fridges in every home. The gel's melting point can also be altered by modifying the molecular weight of the LBG. This is more beneficial for processing than for giving the gel a melt in the mouth feeling.

Chewy Candies

Cream Cheese - Texture & Viscosity