Hydroxyethyl cellulose, HYE-C, is used as thickener, suspending, dispersing, water retention & binding agent & protects various colloidal systems.

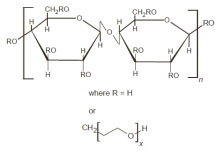

HYE-C or HEC is made by reaction polymerization of naturally obtained cellulose with sodium hydroxide & ethylene oxide. In the synthesis, the average number of moles of ethylene oxide that combines with each mole of cellulose & is controlled between 1.5 to 2.5. The number of hydroxy ethoxy groups are present typically in the range of 30 to 70%.

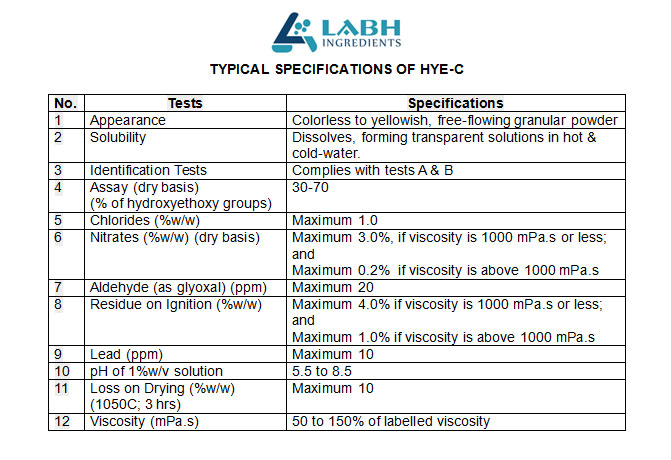

Hydroxyethyl cellulose, HYE-C, is a colorless to yellowish, free-flowing granular powder which dissolves easily into hot & cold-water giving shear thinning transparent solutions. The solutions have varying viscosities depending on type or MS of HEC, concentration & temperature. Molecular weight & degree of polymerization of HEC is directly proportional to viscosity.

HEC - HYE-C

Pharmaceutical Syrup with HEC

Low & Intermediate viscosity grades of HEC are completely soluble in glycerol & good solubility in hydroalcoholic solutions that have 60% alcohol. HEC is insoluble in organic solvents. Non-ionic nature of HEC makes it less sensitive to pH changes.

Industrial applications of HEC are varied due to its water-binding, thickening abilities, & stability to wide range of pH due to its non-ionic nature. Thus, it is used in :

Water based Paint with HEC

Toothpaste with HEC

Water based inks, paints

Personal Lubricants with HEC

Large bubbles