INCI Name : Acrylates Copolymer

Chemical Name : Acrylic Copolymer in Emulsion

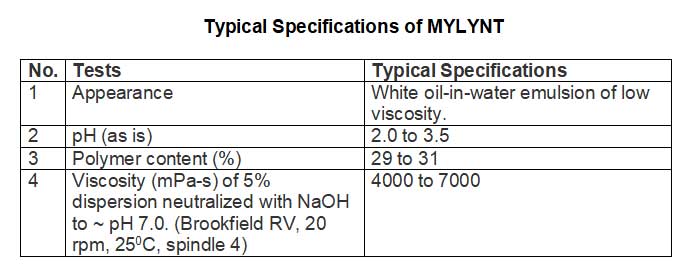

MYLYNT is an anionic acrylic copolymer white emulsion which shows rapid dispersion in water and starts to swell in water at pH 6.0.

In the presence of surfactants, viscosity builds up at lower pH. Aqueous dispersions of MYLYNT can be neutralized using inorganic or organic alkaline bases in pH range of 6.5 to 12.0. These neutralized aqueous dispersions have medium viscosity, good clarity and high yield values and exhibit pseudoplastic behavior.

MYLYNT is miscible and compatible with various surfactants, exhibiting thickening and viscosity buildup at lower pH.

MYLYNT Dispersion

A high suspendibility and stability of formulations is achieved when MYLYNT is formulated with surfactant systems and which can comprise of insoluble materials beads, capsulets, pumice, pearlizing & opacifying agents, pigments, zinc pyrithione, luffa, walnut shell, and polyethylene.

MYLYNT is used to stabilize cosmetic ingredients like silicone oils, various immiscible oils, vitamins, fragrances in the surfactant systems.

Using MYLYNT, one can prepare milky white and creamy shower gels with good emollience, along with various oils like silicones, avocado oil, macadamia oil, sunflower oil, vitamin E, etc.

MYLYNT is suitable for formulation of clear fluid gels and for stabilizing oil-in-water emulsion systems and for those formulations which have a high pH.

In the case of shampoos and body washes, MYLYNT provides the best performance in terms of viscosity, clarity, and yield values at low pH of 4.5 to 5.5 which is required for Sodium benzoate &/or Benzoic acid preservative efficacy.

MYLYNT can be used in formulations for hair styling.

MYLYNT is used, as is, between 1-10% depending on desired viscosity.

MYLYNT shows excellent compatibility with surfactant thickeners (such as Cocamide DEA, Cocamide MEA, Cocamide MIPA, PEG-120 Methyl Glucose Dioleate, PEG-18 Glyceryl oleate/cocoate etc.) and with salts such as NaCl and, if additional thickening is required, a combination of the polymer with these surfactants and/or NaCl can be used; imparting excellent suspending properties to formulations.

The addition of electrolytes decreases the clarity of polymer containing compositions. However, in the case of MYLYNT, the addition of moderate amounts of NaCl may cause a negligible loss of clarity.

MYLYNT instantaneously dissolves in water and after neutralization with an appropriate base, a clear gel is formed.

Adding MYLYNT to thicken Shampoo or Bodywash

Excessive agitation should be avoided to prevent entrapment of air bubbles, which are difficult to remove from the finished formulation.

Suitable neutralizing agents are inorganic bases (like NaOH, KOH & Ammonia solution) or organic amines (such as Triethanolamine, various aminomethyl phenols and 2-Amino-2-methylpropane-1,3-diol {AMPD}). The bases used should be diluted in water up to a maximum of 10%, preferably between 2 to 5% before use.

ln the case of emulsions MYLYNT can be added during any step of the production process. Addition of bi- and tri-valent cations can cause a drop of viscosity.

Gels prepared with MYLYNT neither prevent nor promote the growth of microorganisms; provision should be made for the addition of a suitable preservative system in formulations.

UV-light causes a drop viscosity of MYLYNT gels due to polymer chain degradation; thus, water soluble UV absorbers like Benzophenone-4 can help to avoid this.

| Applications | Uses |

|---|---|

| Skin and Sun-care formulations | Lotions, creams |

| Bath & Shower formulations | Shower gels, shampoos, liquid soaps, foam baths |

| Haircare formulations | Haircare emulsions |

| Other formulations | Shaving products, liquid make-up products, depilatories |

MYLYNT is not expected to be dangerous to health if usual hygienic measures common in the industry are taken.

Disclaimer : The information contained in this data sheet is based on our current knowledge. However, no warranty, whether expressed or implied, including warranties of fitness for a particular use or purpose, are made. Products made using MYLYNT must be evaluated by the user for suitability in production and usage. We assume no responsibility for infringement of patent rights that may arise from the use of the product. For industrial use only.